Engineering, precision, and innovation in facade design

Seoul, South Korea

A seamless synthesis of performance and expression

|

Project location: |

Seoul, South Korea |

|

Project type: |

Mixed-use building |

|

Neolith Materials: |

Neolith Arctic White, Neolith Perla, Neolith Pietra di Luna, Neolith Cement |

|

Design: |

L’EAU Design Studio |

|

Partner: |

GAI International |

Located in Seoul’s Sinsa district, the Sinsa Polyomino building represents a precise synthesis of architectural geometry, engineered performance, and material integrity. Designed by L’EAU Design Studio and executed in collaboration with GAI International, Neolith’s distributor in South Korea, the project explores advanced facade engineering, precisely integrating Neolith surfaces within a ventilated facade system designed to ensure maximum efficiency and climatic resistance.

By aligning conceptual rigor with a thoroughly detailed constructive process, the building stands as a benchmark for refined facade design in an urban context characterized by density, variability, and environmental stress.

Architectural rationale and compositional strategy

The architectural framework of Sinsa Polyomino is guided by geometric order and controlled repetition. L’EAU Design Studio conceived the facade as an articulated surface composed of interconnected panels that establish a rhythmic pattern through precise alignment and proportional calibration. The composition rejects ornamental excess in favor of an analytical approach where geometry, proportion, and repetition define the building’s visual and structural logic.

“The idea draws inspiration from film editing and urban storytelling, using modular, repeatable spaces like polyomino shapes to let each user create their own narrative as they move through the city. Rather than a single linear story, the project invites multiple interpretations and experiences, challenging uniform urban development.”

- L’EAU Design Studio

This compositional methodology dictated both the structural layout and the facade assembly. Dimensional control was central to ensuring alignment between architectural intent and constructability, with Neolith panels serving as both visual and protective layers within the overall facade system.

Specification and material performance

The selection of Neolith sintered stone was driven by its advanced material properties and compatibility with ventilated facade systems. Engineered through high-pressure sintering, Neolith panels provide exceptional resistance to thermal shock, chemical agents, and ultraviolet radiation, while maintaining dimensional stability across a wide temperature range.

GAI International specified a controlled palette consisting of Neolith Arctic White, Neolith Perla, Neolith Pietra di Luna, and Neolith Cement. The chromatic variation between tones enhances the geometric articulation of the facade while ensuring long-term color stability and low maintenance under Seoul’s high urban pollution levels. The surface properties of Neolith—non-porous, stain-resistant, and highly dense—reduce maintenance cycles and minimize water absorption, critical for environments subject to seasonal humidity and airborne contaminants.

“The palette was calibrated to achieve chromatic balance under variable daylight conditions. Each surface performs consistently across different exposures, contributing to an even and durable visual field.”

- L’EAU Design Studio

System configuration and assembly methodology

The facade was executed using a ventilated system developed by GAI International, adapted to local regulations and site-specific conditions. While conceptually similar to Neolith’s HC System, it integrates the Korean company’s own anchoring profiles and brackets.

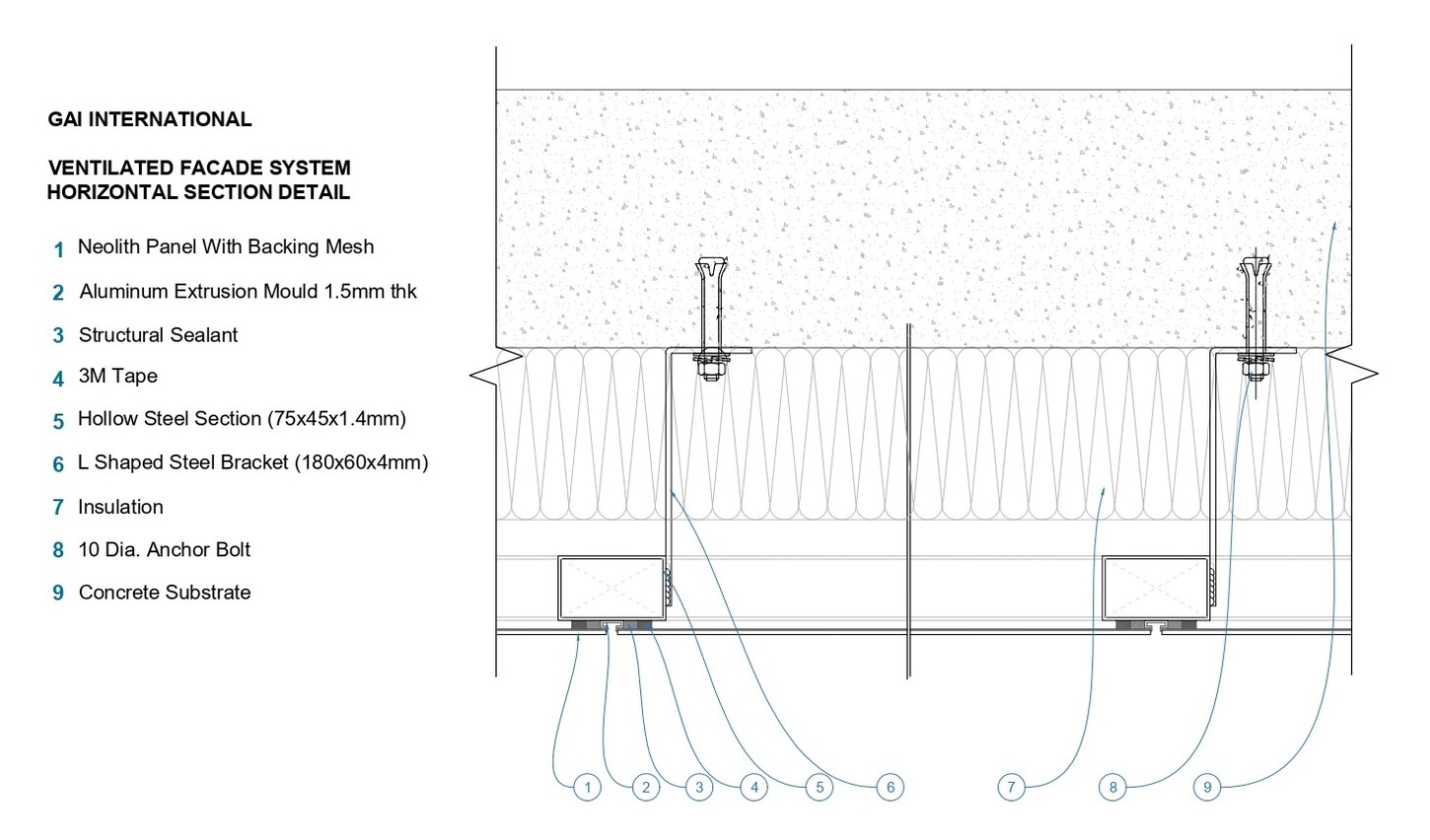

The system is configured as a multi-layered stratified assembly, comprising:

1. A reinforced concrete structural wall.

2. Continuous exterior thermal insulation.

3. A ventilated air cavity for hygrothermal regulation.

4. An steel subframe fixed to the primary structure through adjustable anchors.

5. Neolith panels installed using a chemical bonding system.

Detail of the ventilated facade system for the Sinsa Polyomino project. Image courtesy of GAI International.

This configuration ensures independent behavior of each layer, allowing for controlled ventilation, moisture drainage, and dimensional flexibility. The substructure was engineered to accommodate both vertical and horizontal tolerances, ensuring precise panel alignment across the entire envelope.

“Our facade solution relies on controlled joint spacing, mechanical reliability, and full drainage continuity. It maintains consistent performance under Korea’s temperature fluctuations, high humidity, and exposure to particulate pollution.”

- GAI International

Environmental and structural performance

Seoul’s continental climate presents considerable demands on building envelopes, including extreme temperature differentials, high summer humidity, and frequent freeze-thaw cycles. To address these factors, the system incorporates expansion joints positioned at strategic intervals to manage thermal movement and mitigate stress accumulation on the panels and subframe.

The ventilated cavity promotes continuous airflow, reducing surface condensation and ensuring the evacuation of moisture from the insulation layer. Combined with Neolith’s negligible porosity and non-capillary structure, this assembly minimizes the risk of biological contamination and surface deterioration over time.

Neolith’s high flexural strength and resistance to impact ensure long-term stability against wind loads and mechanical stress. The material’s low thermal conductivity contributes to improved energy efficiency, while its inherent UV stability guarantees consistent color performance under prolonged solar exposure.

Detailing and junction resolution

The project’s execution emphasized precision detailing at intersections, corners, and openings. Each junction was resolved to maintain the visual and structural coherence of the facade while ensuring compliance with waterproofing and ventilation requirements.

Corner conditions were designed using continuous panel alignment and concealed brackets, avoiding cut edges to preserve material integrity. Horizontal terminations at floor slabs integrate drainage and ventilation components to manage moisture accumulation. Vertical joints were dimensioned to accommodate thermal expansion and differential movement between the structural substrate and the steel subframe.

Window openings were detailed with secondary steel framing profiles to to eliminate thermal bridging and ensure efficient water drainage. All visible joints were minimized to achieve a clean, uninterrupted surface reading, consistent with the geometric precision established in the design phase.

Integration of concept and constructability

Although L’EAU Design Studio and GAI International operated independently during design and execution, both teams shared prior experience in projects incorporating Neolith facades, which established a technical foundation for the detailing process. Lessons from earlier applications of Arctic White and Nero informed dimensional coordination, fixing patterns, and material tolerances, ensuring a coherent relationship between architectural expression and construction methodology.

“The design team did incorporate lessons and aesthetic ideas from our previous Neolith facade projects, such as those using Arctic White and Nero. This continuity ensured aesthetic cohesion with proven local references.”

- L’EAU Design Studio

The resulting envelope demonstrates a high degree of integration between design, material performance, and system engineering. The controlled repetition of panels and calibrated joint patterns produce a rhythmic facade that balances compositional rigor with environmental responsiveness.

Performance-driven architectural synthesis

Sinsa Polyomino exemplifies a performance-driven approach to contemporary facade design, where material science, environmental adaptation, and architectural precision converge. The use of Neolith as the primary cladding material ensures long-term durability, minimal maintenance, and stable performance under Seoul’s demanding climatic conditions.

By combining Neolith’s intrinsic qualities with a rigorously engineered ventilated facade system, the project achieves an equilibrium between aesthetic discipline and functional reliability. Its facade operates as a self-regulating envelope—ventilated, insulated, and structurally optimized for safety and longevity.

In an increasingly performance-oriented architectural context, Sinsa Polyomino stands as a reference for technically advanced envelope solutions in dense urban environments, where precision, efficiency, and resilience are essential design parameters.

Technical sheet

Location: Seoul, South Korea

Typology: Mixed-use building

Architecture firm: L’EAU Design Studio

Distributor / Facade system: GAI International

Area: 915 m²

Materials: Sintered stone

Colors: Neolith Arctic White, Neolith Perla, Neolith Pietra di Luna, Neolith Cement

Fixing system: GAI International ventilated facade system

Performance features: Waterproofing, drainage, ventilation, high insulation, weather resistance, self-cleaning surface

Completion year: 2024